Valve Assembly

time:2021-02-27 15:56 views:

Valve assembly is the key component of the hydraulic end of mud pump. Its working frequency is high and its impact is large. Its quality directly affects the service life of liquid cylinder, and it is the main vulnerable part of mud pump. The valve assembly consists of the valve body and the seat. Accordingly to the form of liner hole of the valve seat, valve assembly can be divided into 3 bars valve,4 bars valve and through-hole valve.

The valve body and the valve seat valve assembly is made of high quality alloy steel 20CrMnTi carburizing and quenching, surface hardness greater than HRC60, the cone grinding to ensure high roughness and geometry. The polyurethane material is used to make the whole life of the valve assembly greatly improved, and the effective use time is more than 300 hours. The body assembly is composed of valve body, valve rubber, valve nut, guide frame, cap, spring, steel ball and so on.

Product description:

The mud pump valve and seat are made of forged alloy steel with deep carburized wear surface. We offer a full range of valves and seats which include 3 bars,4 bars and through-hole.

Through-hole Valve and Seat

The mud pump valve comes with through-hole seat features with four guide wings. They are either inertia welded to the valve body or uniformly forged with valve body. The urethane insert can be easily snapped on.

3 bar / 4 bar Valve and Seat

The 3 bar / 4 bar valve seat comes with stem guided valve. The urethane insert is tightened by steel plate and nut. It can be easily replaced with minimum down time. They offer long lasting service life under harsh service conditions.

Product features:

1. Forged alloy construction

2. Deep carburized wear surface

3. Precision machined to API standard

4. Urethane inserts

5. Rubber inserts

6. Associated parts

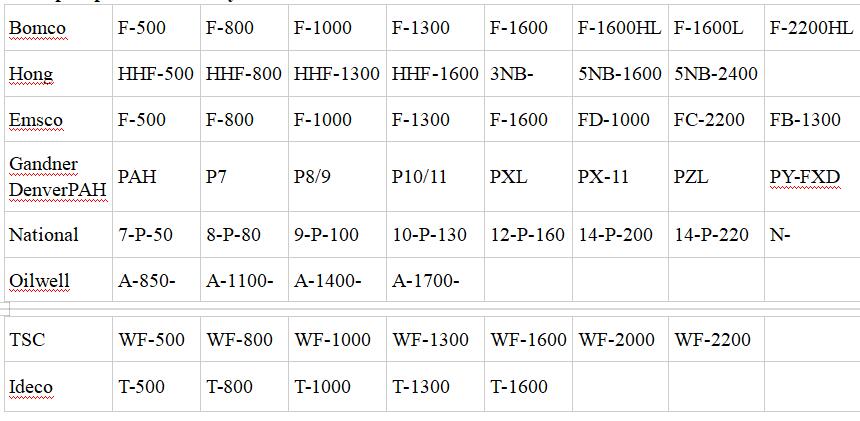

Mud pump valve assembly model: